Our production lines

In addition to our standard machine range, we make complete custom solutions. View the possibilities for a custom production line.

The Spako KKL cooking-cooling line is a modular system that allows products to be cooked and then re-cooled. This line can be equipped with a standard cart tipper for automatic feeding of the product. On the output side, you can choose to dispense into a dolav bin, norm trolley or gastronorm bins. In addition, you can optionally pump the product via the Spako pump skid. In addition, the cooking-cooling line can be equipped with various options such as a CIP cleaning system, load cells and an air rake for aeration in the cooking kettle. The Spako cooking-cooling line is extremely suitable for:

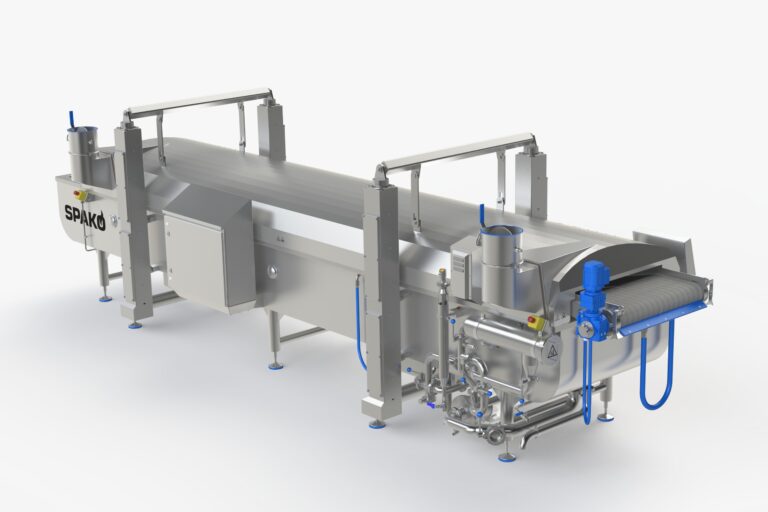

The Spako SCK is an in-line cooking system. It is fully designed with a lower and upper conveyor belt and equipped with a variable-capacity circulation pump. The pressure and guidance of the lower and upper belts ensure high output. At the front of the machine, there is a water flow regulator that controls the water flow through the cooking line. This unit is height-adjustable for precise calibration. In addition, the line can be fully tailored to different products. This allows us to use various types of belts, making it a highly multifunctional machine. This makes the machine particularly suitable for:

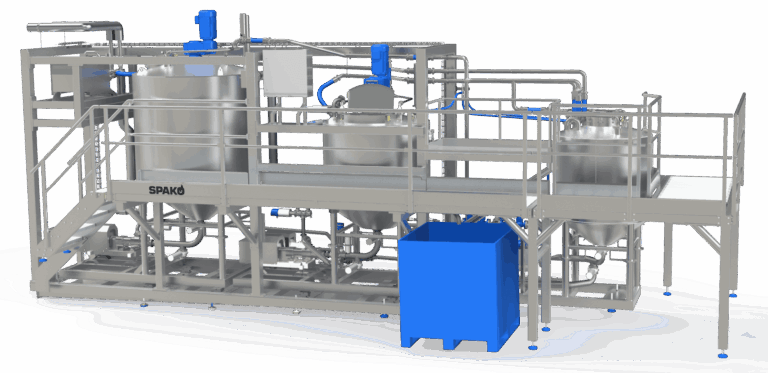

At Spako, we develop and build project-based sauce and soup installations, as well as high-quality buffer tanks, fully tailored to your production process. Our installations offer extensive possibilities for automation and process optimization.

By integrating components such as shear mixers, pumps, CIP systems, and various valves, we create efficient and reliable solutions that perfectly match your requirements and product characteristics.

For buffering products, we supply tanks with options for heating, temperature retention, and cooling, ensuring your product is always processed and stored under the right conditions.

With our customized solutions, you are guaranteed a flexible, future-proof system that elevates your production to the next level.

Besides our standard range of machines, we create complete custom-made solutions. The KRHSI 825 is a great example. This cooking vessel, heated by direct steam injection, has been fully designed according to the customer’s wishes.

The steam injector is positioned freely beneath the basket. The basket itself is made of Trislot screen plates and can tilt forward in front of the machine for easy cleaning.

In addition, the machine is equipped with load cells for weighing the incoming product.

Would you like to configure your ideal machine as well? Let us know!

Have a cup of coffee with Bram. He knows exactly what you need.

Or fill out our contact form on the contact page